Exam Gloves vs. General-Use Gloves: What’s the Difference?

When sourcing disposable gloves, one of the most common questions we hear is:

“Do we really need exam gloves, or will general-use gloves work?”

At first glance, many gloves look similar. But the differences between exam gloves and general-use gloves go far beyond appearance—and choosing the wrong type can impact safety, consistency, and long-term cost.

This guide breaks down the key differences so you can make the right decision for your application.

What Are Exam Gloves?

Exam gloves are designed for environments where reliable barrier protection is critical. They are commonly used in healthcare settings, but their benefits extend well beyond hospitals and clinics.

The defining feature of exam gloves is their stricter quality standards, particularly when it comes to defect rates.

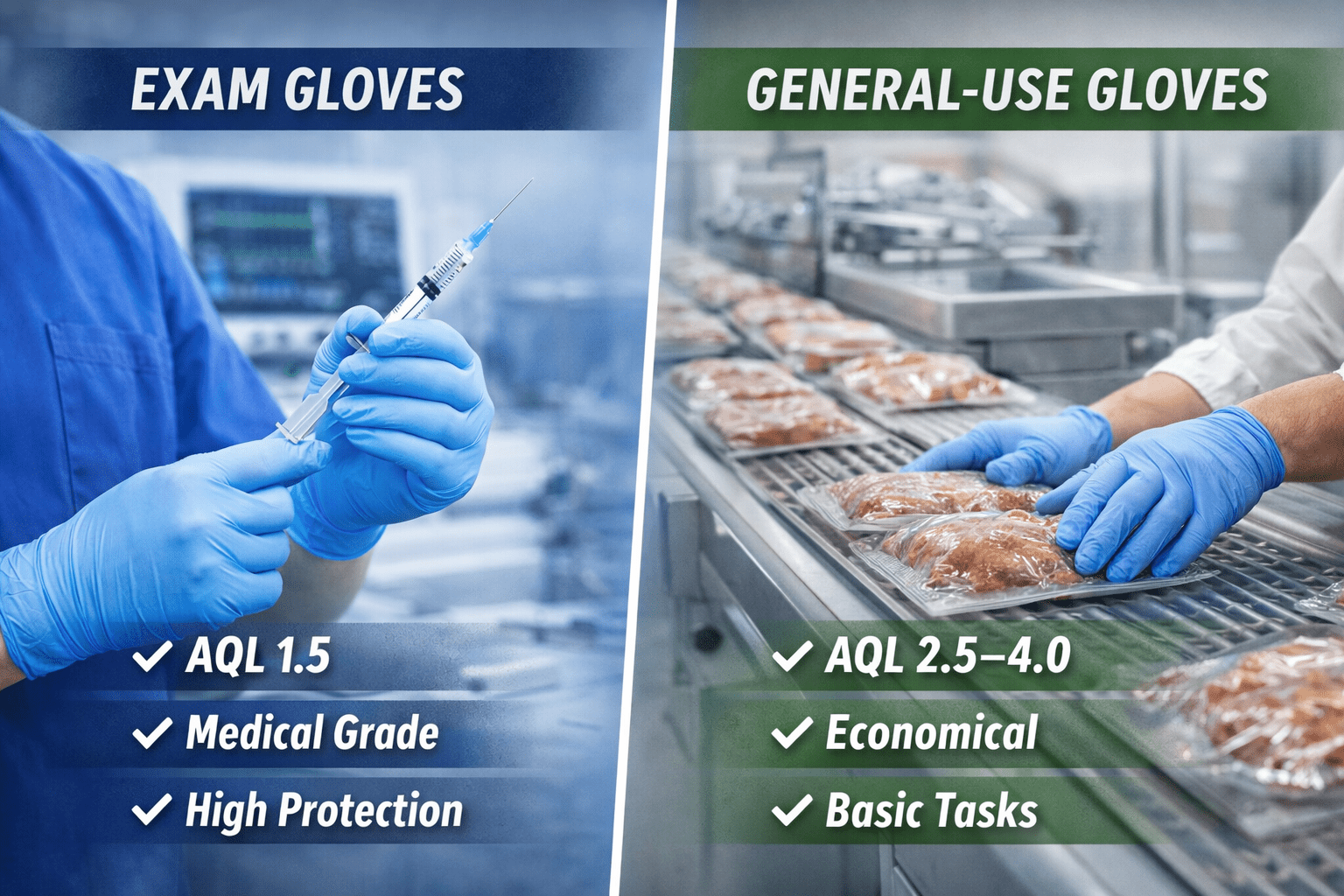

Key Characteristics of Exam Gloves:

-

Tested to AQL 1.5 (Acceptable Quality Limit)

-

Lower allowable defect rate per batch

-

Consistent thickness and strength

-

Often certified to medical and food-contact standards

-

Suitable for extended or critical-use tasks

In simple terms, exam gloves are manufactured and tested to ensure fewer holes, tears, and failures.

What Are General-Use Gloves?

General-use gloves are typically designed for lighter, non-critical tasks where barrier integrity is less essential.

They are often chosen based on lower upfront cost but are produced to less stringent quality standards.

Key Characteristics of General-Use Gloves:

-

Typically tested to AQL 2.5–4.0

-

Higher allowable defect rate

-

More variability in thickness and durability

-

Best suited for short, low-risk tasks

-

Lower cost per box, but often higher usage rates

Understanding AQL: Why It Matters

AQL (Acceptable Quality Limit) measures how many defective gloves are allowed in a production batch.

-

AQL 1.5 (Exam Gloves):

Fewer than 1.5 defective gloves per 100 tested -

AQL 2.5–4.0 (General-Use Gloves):

Allows significantly more defects per batch

Over large volumes, this difference matters.

For example, across 100,000 gloves, the gap between AQL 1.5 and AQL 4.0 can mean hundreds of additional failures.

Those failures translate into:

-

Glove changes mid-task

-

Increased glove consumption

-

Workflow interruptions

-

Safety and contamination risks

Are Exam Gloves Only for Healthcare?

Not at all.

While exam gloves are required in healthcare settings, their higher quality makes them a better choice for many non-medical industries, including:

-

Food handling & food production

-

Manufacturing & assembly

-

Laboratories

-

Cleaning & janitorial services

-

Automotive & industrial work

Anywhere glove failure creates downtime, waste, or risk, exam gloves often provide better value over time, despite a slightly higher upfront cost.

Cost vs. Value: The Real Math

General-use gloves may appear cheaper per case—but if they tear more often, require doubling up, or need frequent replacement, total usage increases quickly.

Many organizations find that switching to exam-grade gloves:

-

Reduces glove consumption

-

Improves worker efficiency

-

Lowers indirect costs tied to failures

In practice, the cheapest glove is rarely the most cost-effective one.

How to Choose the Right Glove

Ask these questions:

-

Is barrier protection critical for this task?

-

How often are gloves being changed due to tearing?

-

Does consistency matter across shifts or departments?

-

Are we prioritizing lowest unit cost—or lowest total cost?

If reliability matters, exam gloves are usually the smarter choice.

Final Thoughts

Disposable gloves may seem like a small detail, but they play a critical role in safety, efficiency, and compliance. Understanding the difference between exam gloves and general-use gloves helps ensure you’re choosing the right protection for your team and your operation.

At AP Medical Supply, we help organizations evaluate glove quality, standards, and real-world performance so they can make confident, informed decisions.

If you’re reviewing your glove strategy for the year ahead, we’re always happy to help.